Think of ordering an online order for a small item or an order for a takeaway dinner and finding it packed in a large bag or another large cardboard box that seems flimsy or unnecessary. The product could be of very good quality, but it would have been devalued with that packaging.

This is more than a design bug.

It is often the “hidden cost of dependency on limited suppliers.”

If brands are tied to a small number of suppliers, negotiation power, flexibility, and packaging choices are all diminished. The effect? Small products in big bags, irregular box strength, increased costs, and a subpar user experience.

In a market that presents consumers as a first experience of physical handling by the brand itself through the package, such trade-offs can quietly destroy trust.

Table of Contents

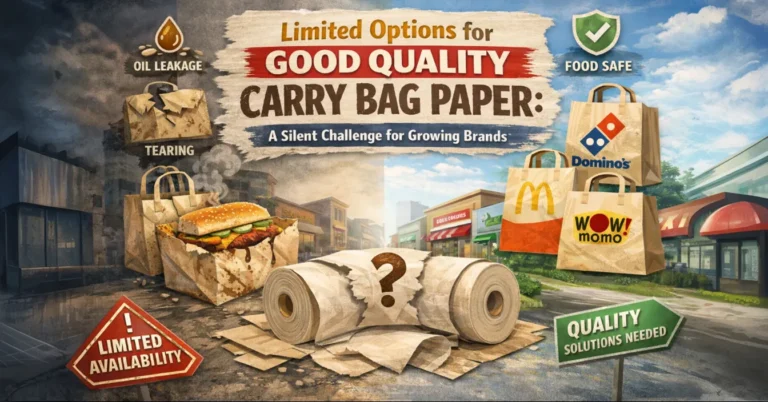

The Root of the Problem: Limited Supplier Dependency

Brands across various industries, such as retail, Quick Service Restaurants, FMCG, and the e-commerce industry, among others,

- Reliance on 1-2 approved paper suppliers

- Fixed paper size with limited scope for improvements

- Limited availability of other paper qualities or grades

- Decreased bargaining power with respect to price, lead time, and flexibility.

Brands dictate performance, but suppliers dictate availability, and this condition generates a forced choice regarding the package in which the product will arrive.

This is where inefficiencies get introduced:

- Lightweight products that are placed in heavy bags.

- Packages of foodstuffs that have non-uniform stiffness

- Premium-looking but weak bags

- Many converters with varying paper quality, causing inconsistency throughout locations.

Why Packaging Fit Matters More Than Ever

Everything is noticed by the modern-day consumer

A miniature burger boxed inside a giant paper box does not exude quality—it’s negligent. A package with a dented appearance upon arrival reflects low quality. The packaging may carry a powerful brand identity, but a weak carry bag is a failure point.

In fact, for brands such as Vishal Mega Mart, Instamart, Zomato, Blinkit, Zepto, Swiggy, Reliance Retail, the package isn’t just a package; it is an experience based on standardization, right-sizing, and uniform paper quality.

The Shitla Papers Approach: From Dependency to Design Control

“At Shitla Papers, the emphasis isn’t just on delivering packaging paper. They solve the problem of packaging at the root.”

With a strong presence in over 11 countries, Shitla Papers specializes in facilitating you in selecting appropriate paper quality for your applications. Such consistency ensures that even in situations involving multiple paper converters or suppliers, you get what you need.

Whether it’s:

- Paper carry bags

- Food paper boxes (burgers, wraps, fries)

- Paper cups and lids

- Napkins & tissue

- Food box inner liners

- Cutlery pouches

- Paper pouches and mailers

The aim is the same:

“Standardized strength, quality, look and feel—across all points of touches.

Smart Paper Selection: The Real Solution

The key to dealing with supplier dependency is paper intelligence, not paper excess.

“Shitla Papers has a broad product line, enabling the brand to achieve optimal, as opposed to oversized, packaging”:

Important Key Paper Solution:

- Kraft Top Liners – Virgin Kraft Top Liners For Use With Surgery or Biopsy

- Kraft Liner Boards – Reliable performance for corrugation

- High Performance Fluting Mediums – Improved compression without adding GSM

- White Top Kraft Liners – Clean, premium look with strength

- Corrugation Paper (Liner + Fluting) – Designed for right-sized boxes

- Virgin / Test Liners – Versatility in handling varying loads

- Kraft Wrapping Paper – The best wrapping paper for compact and environment friendly packages.

- Greaseproof Sheets – Ideal for use with food without leakage

Rather than “one paper fits all” solutions, brands are provided with paper tailored for their particular applications.

Customization That Restores Control

One of the major benefits of working with Shitla Papers is its technical customization.

All materials are made under strict quality controls and can be adapted to your needs for:

- BF (Burst Factor

- RCT (Ring Crush Test

- SCT (Short Span Compression Test)

- ECT (Edge Crush Test)

- GSM

- Cobb Value

- Total Stiffness & Strength

This implies that:

- No paper is wasted

- No Oversize bags for Small Products

- No poor quality packaging for heavy goods

- No inconsistency among vendors

Only right-fit packing, doing exactly what is expected.

Reducing Costs Without Compromising Experience

When paper quality is uniform for all converters:

- Negotiation power is

- Wastage

- There are fewer instances

- Customer complaints decline

Brands now do not have to compensate for strength through the use of scale or thickness, and instead, engineered strength is now smarter, slimmer, and more sustainable.

This is how brands can transition from reactive packaging to strategic packaging.

The Bigger Picture: Consistency Builds Brand Trust

The customer may forget the commercial, but they remember the feel of the package.

When there is uniform packaging in the same city, stores, as well as delivery partners, silent trust is generated. It can be a coffee cup in Delhi, a burger box in Mumbai, or a mailer in Bengaluru, but the experience should be the same everywhere.

It can only happen if brands emancipate themselves from being constrained suppliers and collaborate with a paper expert who is a solution provider.

Final Thought

Packs of small goods are not only inefficient, but they also convey a lack of direction in packaging choices.

Brands get back under control with the proper paper partner.

Shitla Papers enables Brands to:

- Cut or Optimize

- Establish quality standardization with vendors

- Improve customers’

It’s about using the right paper.