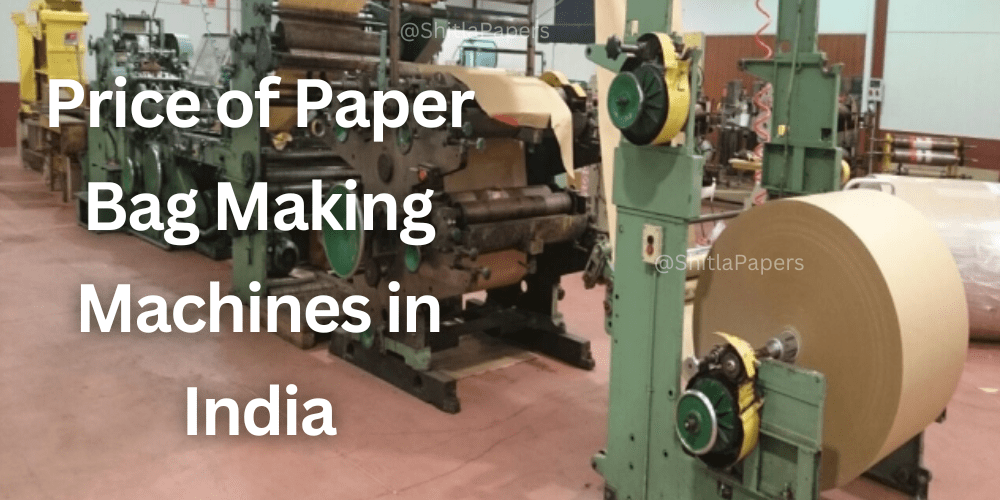

Introduction : Price of Paper Bag Making Machines in India

In a world that is increasingly conscious of environmental concerns and the need to reduce plastic usage, paper bags have emerged as a sustainable alternative. India, with its vast population, has recognized the importance of eco-friendly packaging solutions. As a result, the demand for paper bags has surged, and so has the interest in paper bag making machines. In this blog, we will discuss the price range of paper bag making machines in India, uncovering their prices and the factors that influence them.

Understanding the Types of Paper Bag Making Machines:

Before we dive into the price range, it’s essential to understand that paper bag making machines come in various types and sizes, each serving a specific purpose. Here are the primary categories:

- Manual Paper Bag Making Machines: These are small, manually operated machines ideal for small-scale businesses. They require significant human intervention.

- Semi-Automatic Paper Bag Making Machines: These machines strike a balance between manual and fully automatic systems. They offer higher production rates and reduced labor requirements.

- Fully Automatic Paper Bag Making Machines: These state-of-the-art machines are designed for large-scale production, offering high efficiency and minimal manual intervention.

Factors Influencing the Price:

Several factors determine the price range of machine:

- Machine Type and Capacity:

The type and production capacity of a paper bag making machine greatly influence its price. There are different types of machines, including manual, semi-automatic, and fully automatic models. Manual machines are the most budget-friendly, but they have lower production capacities. Semi-automatic and fully automatic machines are more expensive, but they can produce bags in larger quantities. - Brand and Manufacturer:

Well-established and reputable brands tend to offer machines at higher prices. However, they often provide better quality and after-sales support, making them a reliable investment. Lesser-known or newer manufacturers may offer lower-priced machines, but quality and support may vary. - Machine Features:

The price of a paper bag making machine can also vary depending on the features it offers. Some advanced features, such as computerized controls, servo motors, and multi-color printing options, can increase the cost significantly. Evaluate your specific needs to determine which features are essential for your business. - Material Compatibility:

Machines designed to work with a wide range of paper types and sizes may be more expensive. Consider the specific materials and bag sizes you plan to produce and select a machine that meets those requirements to avoid unnecessary costs. - Supplier Location:

The location of the machine supplier can affect the final price due to transportation and import/export fees. Local suppliers may offer more competitive prices and quicker delivery, but international suppliers might provide specialized machines not readily available locally. - Used vs. New Machines:

Buying a used paper bag making machine can significantly reduce costs, but it’s essential to assess the condition of the machine thoroughly and ensure it meets your production needs. New machines often come with warranties and support but at a higher price point.

Price of Paper Bag Making Machines in India:

The price of paper bag making machines in India varies widely depending on the factors mentioned above. As of my last knowledge update in September 2023, here is a rough price range breakdown:

- Manual Machines: ₹50,000 to ₹2,00,000 INR

- Semi-Automatic Machines: ₹2,00,000 to ₹6,00,000 INR

- Fully Automatic Machines: ₹6,00,000 to ₹20,00,000 INR (or more)

Please note that these prices are approximate and can change over time due to market fluctuations, technological advancements, and other factors.

Conclusion:

The paper bag making machine market in India is witnessing significant growth, driven by the increasing demand for eco-friendly packaging solutions. While prices vary based on machine type and features, it’s crucial to make an informed decision by considering your production needs, quality, after-sales support, and operating costs.

Before making any purchase, it’s advisable to research the latest prices, consult with multiple suppliers, and conduct a thorough cost-benefit analysis. By doing so, you can embark on your journey towards contributing to a greener environment and a sustainable business venture in India.

External Links :

Instagram – https://www.instagram.com/shitlapapersofficial/

Facebook – https://www.facebook.com/shitlapaperspvtltd

LinkedIn – https://www.linkedin.com/company/shitla-papers/

Twitter – https://twitter.com/shitlapapers

Buy Eco-friendly food wrapping paper – https://www.ekvee.in/

India’s Paper Industry: A Market on the Rise

At Shitla Papers, we stay ahead of industry trends to keep our partners informed about…

Why Sustainable Paper Sourcing Matters?

Sustainable packaging has become a crucial aspect of modern business practices. As consumers demand more…

How Digitalization is Transforming the Paper Industry?

The paper industry, once known for its traditional manufacturing processes, is undergoing a significant transformation…

Shitla Papers at AAHAR 2025: A Successful Showcase of Sustainable Packaging

Shitla Papers recently participated in the 39th AAHAR International Food & Hospitality Fair, held from…

How Strong Paper Bags Can Boost Ecommerce Sales?

In the fast-paced world of ecommerce, every detail matters. From product presentation to delivery experience,…

Sustainable and Durable Kraft Paper Solutions for Your Packaging Needs

In an era where sustainability and durability are paramount, kraft paper has emerged as a preferred choice…