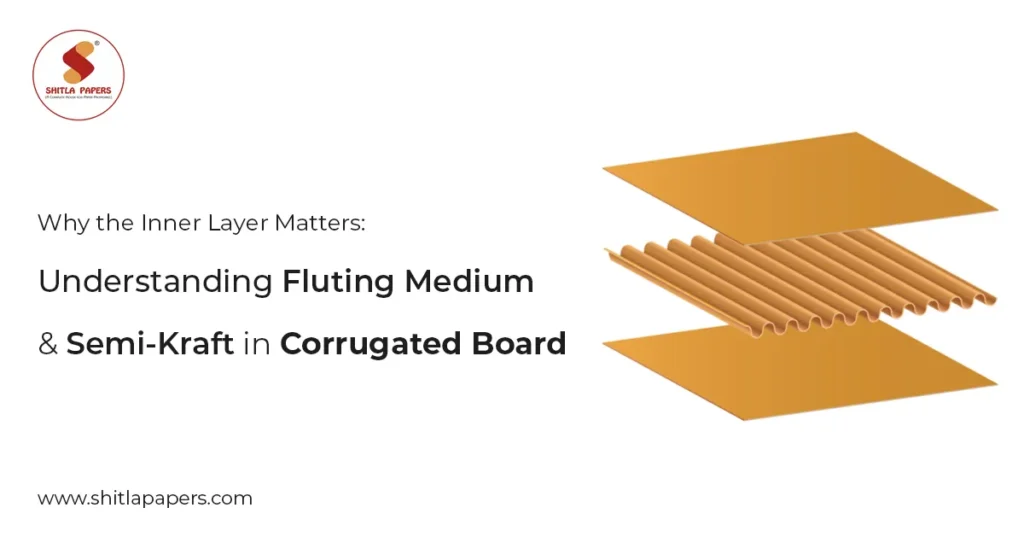

When we think of corrugated boxes, the first image that pops into our minds is usually the sturdy brown box that protects everything from delicate glassware to heavy machinery. But what really gives these boxes their strength and resilience isn’t just the outer liner — it’s the inner layer, the unsung hero that works behind the scenes to maintain structure, cushioning, and durability. This inner layer is known as the fluting medium, often made from semi-kraft paper, and it plays a far more important role than most people realize.

Table of Contents

Let’s dive deeper into what makes the inner layer so critical — and why fluting medium and semi-kraft paper deserve a spotlight in the world of corrugated packaging.

The Backbone of Corrugated Packaging: The Fluting Medium

At the heart of every corrugated board lies a wavy or arched structure called the flute. This fluting medium is sandwiched between two flat linerboards — forming what we commonly refer to as single wall, double wall, or triple wall boards, depending on the number of layers.

But those arches are not just for looks — their shape and material composition are what provide the box its ability to absorb shock, resist compression, and maintain rigidity.

Here’s what happens inside:

- The flutes act as tiny vertical columns, distributing weight evenly.

- They absorb impacts during transit, protecting products from vibration and damage.

- They prevent the board from collapsing under pressure.

Semi-Kraft Paper: The Unsung Hero of Durability

While many people focus on the outer liner for aesthetics and printing quality, the semi-kraft paper used for fluting is what gives a box its soul.

Semi-kraft paper is made primarily from recycled fibers blended with virgin pulp, achieving a balance between strength, flexibility, and cost-efficiency. It’s designed to hold the fluted shape without cracking or tearing — even when exposed to high-speed corrugation processes and varying humidity conditions.

Key Features of Semi-Kraft Paper:

- High Burst Strength: Withstands pressure and protects against punctures.

- Good Ring Crush Test (RCT) Value: Indicates superior compression strength.

- Moisture Resistance: Helps maintain performance in humid storage or transit conditions.

- Eco-Friendly Composition: Usually made from 100% recycled or partially recycled fibers.

Due to its toughness and sustainability, semi-kraft paper is widely used as a fluting medium in packaging for food, consumer goods, electronics, and industrial applications.

The Science Behind the Fluting Structure

There’s a fascinating bit of engineering hidden inside every corrugated sheet. The geometry of the flute determines how the board behaves under different conditions.

Common flute types include A, B, C, E, and F, each offering a different balance of cushioning and printability. For example:

- A-Flute: Offers excellent cushioning and thickness — ideal for fragile items.

- B-Flute: Denser, providing better stacking strength for retail packaging.

- C-Flute: A balanced all-rounder used for most shipping boxes.

- E & F-Flute: Thinner, perfect for premium printed cartons and display packaging.

No matter the flute type, the quality of the fluting medium paper is what ensures the consistency of the arches. Inferior paper can cause crushed flutes, poor adhesion, or uneven board thickness — all of which weaken the packaging.

Inner Strength that Protects the Outer Image

It’s easy to underestimate the importance of what’s hidden inside. However, for brand owners, manufacturers, and logistics teams, the inner layer often determines the overall quality perception of the packaging.

A poorly structured inner layer can lead to:

- Boxes collapsing during stacking or transport

- Damage to packed goods

- Increased replacement and shipping costs

- Negative impressions of product quality

By contrast, using high-quality semi-kraft fluting paper ensures every box performs well — holding shape, bearing weight, and keeping products intact from warehouse to doorstep.

Sustainability and the Semi-Kraft Advantage

Today’s packaging world is evolving fast — and sustainability is no longer a buzzword but a responsibility. Semi-kraft fluting paper plays a big role in this shift.

Because it’s made largely from recycled fibers, it helps reduce waste and energy consumption. At the same time, semi-kraft retains enough virgin fiber content to maintain performance levels. This makes it an eco-conscious yet durable alternative to 100% virgin kraft paper.

Moreover, corrugated boards made with semi-kraft and recyclable liners are fully biodegradable and compostable, making them ideal for brands striving for green packaging credentials.

Why the Inner Layer Truly Matters

Think of the inner layer as the invisible muscle of your packaging. You might not see it, but you’ll definitely feel its impact. It defines:

- Strength – by resisting crushing and bending forces

- Durability – by maintaining shape through long shipping cycles

- Sustainability – by using eco-friendly materials

- Performance – by ensuring consistent protection for every product

Every brand that cares about product safety, customer satisfaction, and environmental responsibility should give as much attention to the fluting medium as they do to their printed outer box.

Final Thoughts

In the world of corrugated packaging, the beauty isn’t just skin deep. The outer layers may catch the eye, but it’s the inner fluting medium and semi-kraft paper that give your packaging its heart and backbone. Investing in high-quality inner layers means fewer damages, happier customers, and a more sustainable planet.