A customer steps out of an upmarket shopping destination, possibly ZARA, H&M, Pantaloons, Fabindia, or Reliance Trends, with carefully selected shopping bags in hand. The item is faultless, the experience at the shopping destination is memorable… only for the shopping bag to rip at the handle point. Or the box to fall apart on the way home.

Suddenly, the brand experience ruptures.

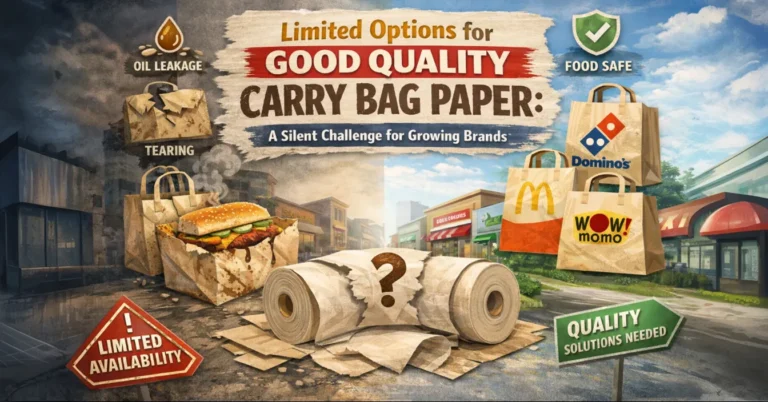

This is perhaps one of the most common yet most overlooked challenges in packaging: the quality of the paper used is not standardized, resulting in torn carry bags, broken boxes, poor shelf displays, and consumer dissatisfaction.

At Shitla Papers, we have an everyday problem and, more importantly, a solution to it.

Table of Contents

The Real Problem: Inconsistent Paper Quality Across Packaging

In fact, many brands find themselves experiencing packaging failures not necessarily as a result of their design but because of the quality of the papers used.

Below is how this problem manifests:

- The carry bags tear while being loaded with slightly heavier goods

- Cartons collapse when stacked or transported

- There is a lack of stiffness or a luxury feel with clothing packaging

- Wrapping paper wrinkles, yellows, or tears easily

- Tags, Labels & Inserts – Ununiform color & strength

“The root cause?”

Unstandardised paper sizes, varying in terms of GSM, burst factor, fiber, and finish, which is provided by different converters.

This is why irregularities in paper quality will inevitably affect the final packaging, irrespective of its print quality.

Why Standardisation Matters More Than Ever

In today’s competitive retail and ecommerce environment, packaging is more than protection; it’s branding.

Customers now associate:

- Strong carry bags with reliability

- Crisp white boards with hygiene and premium quality

- Uniform packaging with brand professionalism

Leading brands like Amazon, Myntra, IKEA, Marks & Spencer, and Decathlon invest heavily in standardised packaging materials because they understand one thing:

A great product is deserving of good, reliable packaging.

Shitla Papers Approach: Solving the Problem at the Source

In other words, at Shitla Papers, we are of the firm opinion that packaging problems have to be addressed even before the manufacturing process starts.

Our materials are produced with rigorous quality norms and can be tailored to fit your needs. For this, our material will be consistent across all shipments, all suppliers, and all geographies.

Our Key Paper Solutions for Standardised Packaging

1. Virgin Kraft Liners

It is perfect for high-strength box packaging applications that demand stacking, compression, and strength. It has optimal burst strength and color consistency, making it perfect for e-commerce and retail box packaging.

2. Virgin Kraft for Paper Bags (Indian Origin)

Specifically designed for paper carry bags, this grade offers better fiber strength, improved fold endurance, and decreased tear resistance at handles. This makes it perfect for both fashion and grocery brands.

In the context of brands which promote the principles of sustainability without any compromise on performance, this kraft paper meets all expectations with respect to strength and look and feel.

4. White Kraft - Both Sides White

This paper is also utilized extensively for luxury packing, gift boxes, and premium carry bags, and it has very good printability and rigidity too.

These are designed especially for corrugated boxes and provide stability to boxes, prevent collapse during transit, and work well with different converters.

6. High Quality Wrapping Paper for Apparels

Soft and sturdy, our wrapping papers are just right for clothes, shoes, and accessories—leaving the customer with a squeaky-clean unboxing experience.

A harmonious blend of beauty and strength, extensively used in branded packaging cartons and carry bags where exterior design is of great significance.

8. Transparent Paper

Particularly for inner wrapping, inserts, or protective layers. It brings a touch of luxury and hygiene to fashion and lifestyle packaging.

One Brand. Multiple Vendors. One Standard.

A major problem for brands is the consistency that is required when there are several converter partners.

Being a prominent player in over 11 countries, Shitla Papers specializes in providing a solution to brands such as yours in the following manner: They assist you in making the right choice regarding the quality of paper needed for the following:

- Carry Bags

- Kurtag

- Box Packaging

- Tags & Labels

- Wrapping papers

We make sure the strength, quality, color, appearance, and feeling continue to be standardized—no matter which converter is providing your packaging.

This means:

- Relatively low number

- Improved alignment with vendors

- Increased brand perception

- Happy Customers

The Business Impact of Getting Paper Quality Right

Brands that standardise their paper quality experience:

- Lower rejection rates

- Reduced transit damage

- Improved customer satisfaction

- Stronger brand recall

- Long-term cost efficiency

Because when packaging performs well, returns reduce, complaints drop, and trust grows.

Final Thoughts: Don’t Let Packaging Be the Weak Link

Your product might be premium. Your design might be perfect. But if your paper quality is inconsistent, your brand experience is impacted.

“At Shitla Papers, we provide paper, but we also make it possible for brands to have consistency, strength, and confidence in their packaging”.